Download aluminum plate information

Download aluminum plate informationFor more aluminium sheet technical documents, Download free in PDF form !! (Haomei-aluminum-sheet.pdf)

Longitudinal cracks in aluminium checker plate sheet

The aluminium checker plate sheet tends to have so…

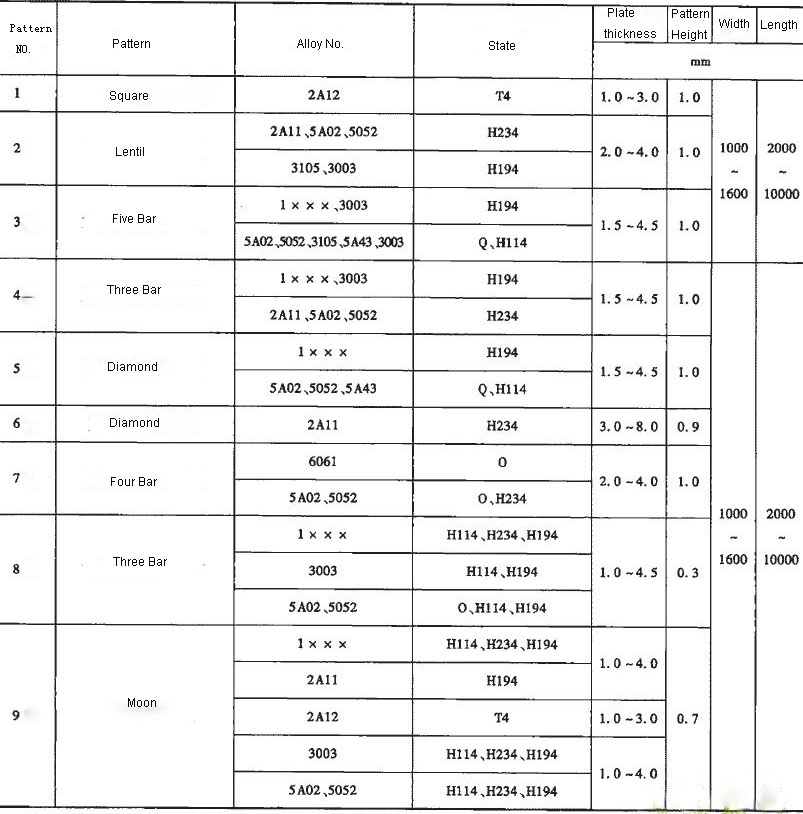

Why The Shape Is Not Same Of Aluminum Checker Sheet ?

In fact, the pattern is not the same shape aluminu…

Our Aluminum Sale Manager Visit To Colombia

On May 12, 2016, our aluminium products sales mana…

Aluminum Tread Plate Popular In Car Is Not Allow To Ignore

For vacant, where needed staff stampede, suggested…

Mirror finish aluminum sheet price

The mirror finish aluminum sheet price ranges betw…

Aluminium checker plate sheet sizes

Aluminium checker plate sheet sizes can be customi…

Stucco embossed aluminum cladding sheet

A stucco embossed aluminum cladding sheet has diff…

Stucco embossed corrugated aluminum sheet

Stucco embossed corrugated aluminum sheets are usu…

Copyright © 2015 - All Rights Reserved - www.saluminium-sheet.com

Aluminum plate Haomei Aluminium

Composition solution for mirror finish aluminum sheet

Hits: 12467 • Add time2019-08-28 16:23:15, author:Haomei Aluminum Plate

The chemical polishing of mirror finish aluminum sheet usually adopts a 70% (mass percent) phosphoric acid based solution. The most commonly used is a mixture of phosphoric acid, nitric acid and sulfuric acid. When the composition of the alloy changes, the sulfuric acid content (mass percentage) is 9%. The change between l5% and the nitric acid content (% by mass) varies between 3% and 9%. Since the working temperature is around 105 °C, a large amount of nitrogen oxides are generated to pollute the environment. Therefore, based on the phosphoric acid and sulfuric acid mixture, the S-type copper brightener is used as an additive to produce a yellow-free chemical polishing process. However, this yellow-free chemical polishing is only suitable for pure aluminum or aluminum-magnesium alloys, like 1050, 1060, 1070, 1100 or 3105 aluminum sheet, and its effect is inferior on other aluminum alloys. Later, there was a formula with only 2% nitric acid, and similar additives were used, which did not expand the scope of application. However, the phosphoric acid, nitric acid, and sulfuric acid mixed solutions are still in the mainstream formulation because of their strong adaptability.

Tagged:mirror finish aluminum sheet, aluminum mirror sheet, aluminum sheet